Table of Contents

ToggleActivated carbon, also known as activated charcoal is a purified form of carbon that possesses the properties like high adsorption of many organic and inorganic compounds, filtration of contaminants, purification of antibiotics, sugar de-colorization, purification of gases, and so on. Moreover, It has a high degree of microporosity.

Typically, carbonaceous source materials (such as nutshells, coconut husks, peat, wood, coir, lignite, coal, and petroleum pitch) are thermally decomposed to produce activated carbon, which is then activated with steam or carbon dioxide, usually in an inert atmosphere with gases like argon or nitrogen, at a high temperature (700–1100 °C).

Activated carbon can be produced by physical or chemical activation.

Types of Activated Carbon

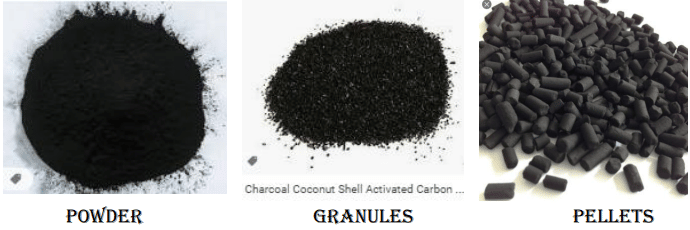

- Powdered Activated Carbon: With certain exceptions, powdered activated carbons typically have particle sizes between 5 and 150 Å. It is frequently employed in liquid-phase adsorption applications and provides lower processing costs and operational flexibility.

- Granular Activated Carbon: Granular activated carbons can be employed in both gas and liquid phase applications and typically occur in particle sizes ranging from 0.2 mm to 5 mm. It is widely used since it is easier to handle and typically lasts longer than powdered activated carbon. They can also be recycled and used again, and they offer increased strength (hardness) too.

- Extruded Activated Carbon: Extruded activated carbons are heavy-duty activated carbon as a result of the extrusion process, and they are typically utilized in gas phase reactions. Their size ranges from 1 mm to 5 mm.

Properties of activated carbon

Activated carbon possesses the properties like high specific surface area, high porosity, and desired surface functionalization. Besides these, some of the major properties are discussed below:

- Pore structure: The source material and production process have a significant impact on the pore structure of activated carbon, which varies. Adsorption is made possible by the pore structure in combination with attraction forces. According to the IUPAC (International Union of Pure and Applied Chemistry), three groups of pores are distinguished; Macropores (> 50 nm diameter), mesopores (2-50 nm diameter), and micropores (< 2 nm diameter). In most cases, the majority of the internal surface area is contributed by micropores. Macro and mesopores are vital for kinetics and can be thought of as the roadways into the carbon particle.

- Hardness: The hardness of activated carbons is maximum in coconut shell-derived activated carbon.

- Adsorptive properties: Adsorption capacity, rate of adsorption, and the overall efficacy of activated carbon are only a few of the factors that make up activated carbon’s absorptive capabilities.

- Particle size: The rate of adsorption depends on the particle size of activated carbon. The particle size of activated carbon used to adsorb minerals like gold should be between 3.35 and 1.4 millimeters (0.132 and 0.055 in). Less than 1 mm-sized activated carbon particles would not be acceptable for elution.

- Surface area: The greater adsorption capacity of activated charcoal is due to its increase in surface area. The greater the surface area, the greater the extent of adsorption.

Preparation of Activated carbon

A. Physical Activation

Utilizing hot gases, the source material is transformed into activated carbons. One or more of the following methods are typically used to accomplish this:

- Carbonization: At temperatures between 600 and 900 °C, carbon-containing material is pyrolyzed, often in an inert environment with gases like argon or nitrogen.

- Oxidation: Raw material or carbonized material is exposed to oxidizing atmospheres (oxygen or steam) at temperatures above 250 °C, usually in the temperature range of 600–1200 °C.

B. Chemical Activation

The raw material is impregnated with specific chemicals, such as phosphoric acid, potassium hydroxide, sodium hydroxide, calcium chloride, and 25% zinc chloride, prior to carbonization. After that, carbonization of the raw material occurs at lower temperatures (450–900 °C).

Typically, the chemical activation and carbonization steps occur at the same time. Due to the lower temperatures and shorter activation times required by chemical activation, it is preferred over physical activation.

Uses of Activated carbon

Activated carbon is used in gas purification, decaffeination, gold purification, metal extraction, water purification, medicine, sewage treatment, air filters in gas masks and respirators, filters in compressed air, and many other applications. Some specific uses are:

- It is very widely employed for the purification of electroplating solutions.

- Activated carbon is used to treat poisonings and overdoses following oral ingestion.

- It has numerous applications in removing pollutants from air or water streams both in the field and in industrial processes.

- It is a permitted substance used by organic farmers when raising cattle and making wine.

- Organic contaminants that can alter the color, flavor, and aroma of vodka and whiskey can be removed using activated carbon filters.

- It has the capacity to store natural gas and hydrogen gas for fuel storage purposes.

- Filters with activated carbon are usually used in compressed air and gas purification to remove oil vapors, odor, and other hydrocarbons from the air.

- In order to recover precious metals like gold and silver, activated carbon is a useful technique.

- In the laboratory, activated carbon is frequently used to purify solutions of organic molecules that contain undesirable colored organic contaminants.

- Since Activated Charcoal is an excellent porous material, it is particularly successful at adsorbing solutes from aqueous solutions.