Table of Contents

ToggleBiosafety cabinets and biosafety laminar hoods are laboratory instruments or equipment mostly used in biological, microbiological, biotechnological labs, etc. Biosafety laminar hood and biosafety cabinet are similar in general but differ in what we are aiming to protect, such as the protection of the product, protection of the environment or the user, or a combination of these three. In general, both are enclosed workplaces, well-ventilated with HEPA filters.

Biosafety laminar hood

Biosafety laminar hoods are also referred to as biosafety laminar airflow. It is an enclosed workspace and is generally used for the protection of products and the environment. It is utilized to safeguard both environment and the product. They are used for the following purposes in the laboratory:

- Preparation and supply of sterile pharmaceutical product

- In different media cultures preparation

- For different antimicrobial and antibacterial test

- For cell culture preparation

- Quality control

- Preparation and pouring of bacterial growth.

In biosafety laminar hoods, UV lights, fluorescent lights, and blowers are present for the exchange of airflow. Depending upon the direction of airflow they are divided into two types:

1. Vertical laminar airflow

Air moves from the top of the cabinet toward the workbench in the vertical laminar airflow.

2. Horizontal laminar airflow

Similar to this, air flows from behind toward the operator in horizontal laminar airflow.

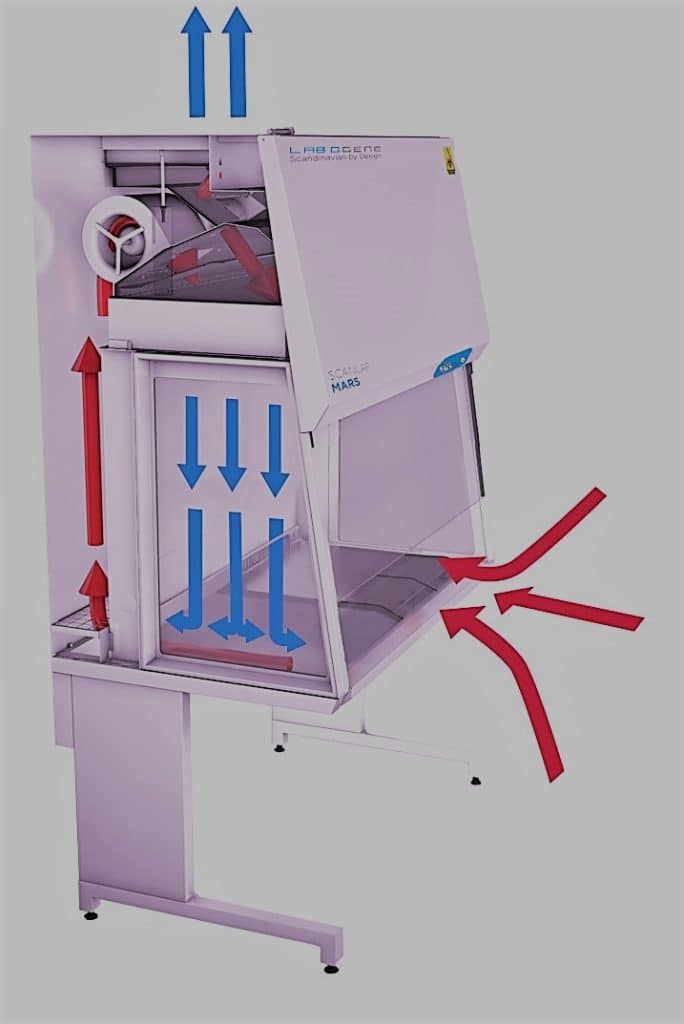

Principal of biosafety laminar hood

The blower air is sucked from the surrounding area, which is then passed through the HEPA filters and discharged into the working space. Most of the air is transported away from the workbench and towards the operator’s face before returning to the surroundings.

Unidirectional airflow with constant velocity and pressure is provided by the laminar airflow cabinets.

External air cannot enter the cabinet because of the pressure inside.

Some laminar airflow systems have UV lighting to sanitize the inner surfaces and parts prior to the procedure.

Due to the lack of operator protection, laminar airflow cabinets are employed for the cultivation of non-infectious organisms.

Biosafety cabinets

A biosafety cabinet often referred to as a microbial safety cabinet, is an enclosed laboratory environment with ventilation for working safely with materials that are contaminated with pathogens and call for specific biosafety levels. In 1950, it was first made available for commercial use.

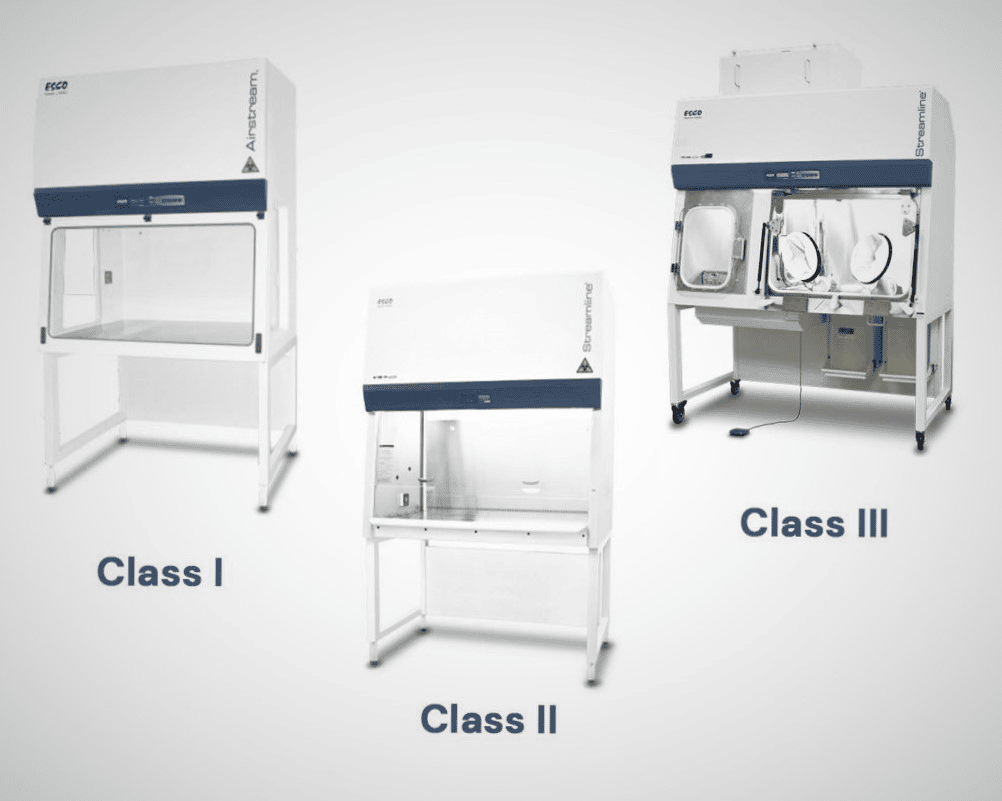

These are for the protection of the products, environment, along with users. Provide personnel product protection. They are divided into three classes.

1. class I

Class I biosafety cabinets are rarely used, and offer protection for the environment and people, but not for the products themselves. Class I cabinets are only useful in some life science applications since they do not provide product protection from contamination.

2. class II

Protection for people, the environment, and products are offered by Class II cabinets. Biological research facilities often use Class II biosafety cabinets, which come in different types including A1, A2, B1, or B2. Class II cabinets are divided into four categories by NSF (A1, A2, B1, and B2) based on variations in airflow patterns and velocities, HEPA air filter positions, ventilation rates, and exhaust techniques.

These hoods are frequently referred to as “chemo hoods” in pharmaceutical environments. A Class II BSC’s open front features inward airflow for personnel safety, downward laminar airflow with HEPA filtration for product protection, and HEPA-filtered exhaust air (environmental protection).

3. class III

ClassIII cabinets are also used for the protection of products, environments, and users. Supply air is sucked into the cabinet through HEPA filters while it is kept in a negative-pressure environment. Either double HEPA filtration or single HEPA filtration is used to cleanse the exhaust air before it is consumed.

Biosafety cabinet Vs Biosafety laminar hood

The differences between a biosafety cabinet and a biosafety laminar hood are:

| SN | Biosafety laminar hood | Biosafety cabinet |

| 1. | It is used to protect products and the environment. | It is used to protect products, the environment as well as users. |

| 2. | They are divided into two classes. They are vertical airflow and horizontal airflow based on the direction of airflow. | They are divided into three classes. They are class I, class II, and class III. |

| 3. | Designed to provide a sterile environment to protect the product. | Designed to provide protection to the environment, users, and products. |

| 4. | They can be utilized for specific sanitary tasks like the clean installation of medical or technological equipment. Never handle drug formulations, possibly infectious materials, cell culture materials, or any other potentially dangerous materials on a clean bench. | As it departs the biosafety cabinet, all exhaust air is HEPA-filtered to eliminate dangerous germs and viruses. This is in contrast to a laminar flow clean bench, which is unsafe for use when working with pathogenic agents because it blows unfiltered exhaust air in the user’s direction. |

| 5. | Biosafety laminar hoods are also called biosafety laminar airflow. | They are also called microbiological safety cabinets. |

Similarity between biosafety cabinet and biosafety laminar hoods

They are both well-ventilated, enclosed workspaces for the protection of products and environments. Both are used for sterilization and make them free from contamination. Both contain HEPA filters for the filtration of environmental as well as the inside air.

Price of biosafety cabinet and biosafety laminar hood

The cost of a Biobase Class Ii Type A2 Biological Safety Cabinet 11231BBC86 ranges from $800.00 to $1,430.00 per unit.

The price range of $600.00–$1,800.00 for an ISO CE Certified Vertical Laminar Flow Hood/Clean Bench.

The price of biosafety cabinet products is between ₹120,000 – ₹145,000 per Piece.

The cost of the Type A2, Class II, Stainless Steel U-Tech Biological Safety Cabinet is around Rs. 1 lakh per unit.

The cost of a Class Iii biological safety cabinet with 230v GI and PU coating is 1.8 Lakh per unit.

The cost of a Gi With Pu Coated Color Coated Laminar Hood, For the Laboratory is 70,000 per piece.

Manufacturing company for these instruments

To ensure laboratory safety and process accuracy, NuAire’s biosafety cabinets use laminar airflow, HEPA filtration, and a robust design. Leading producers of Type A and B Class II biosafety cabinets are Labconco. The company’s BioChemGARD® e3 is the most sophisticated biosafety cabinet that was specifically designed for laboratories that needed to remove and retain vapors, mists, and particulates from the work area.

FAQs/MCQs

What is the difference between class I and class II biosafety cabinets?

Class II cabinets offer more protection for the sample than Class I cabinets, which is the main distinction between the two. The former has no minimum airflow requirements and is unable to provide the sophisticated exhaust system designs found in the majority of Class II cabinet types.

What are A2 Biosafety cabinets?

A Class II, Type A2 cabinet is required to maintain an average inflow velocity through the sash aperture of at least 100 feet per minute. When working with smelly samples or small amounts of chemicals, they, like Type A1 cabinets, may exhaust HEPA-filtered air back into the lab or may be expelled outside using a roof connection.

What is the most common biosafety cabinet?

The most common is Class II Type A2 Biological Safety Cabinets.

References

- www.lamsys.com

- www.pharmaguidelines.com

- https://www.nuaire.com/products/biosafety-cabinets

- https://myfisherstore.com/singapore/the-baker-company-biochemgardr-e3-class-ii-type-b2-biosafety-cabinet-tbc-biochemgard.html