Table of Contents

ToggleA rotary evaporator is very important laboratory equipment mainly used for extracting, distilling, and purifying chemical samples. These are commonly known as Rotavap.

Rotary Evaporator

A rotary evaporator is a laboratory instrument commonly used for the distillation, extraction, and purification of samples. This instrument is very useful for laboratory work and research in various fields such as chemistry, biotechnology, biology, and pharmaceuticals. These are also known as rotary vacuum evaporators since they evaporate solvents in vacuum conditions.

The process of evaporation using a rotary evaporator is called rotary evaporation. Simply, it is evaporation by rotating the sample in a rotating flask.

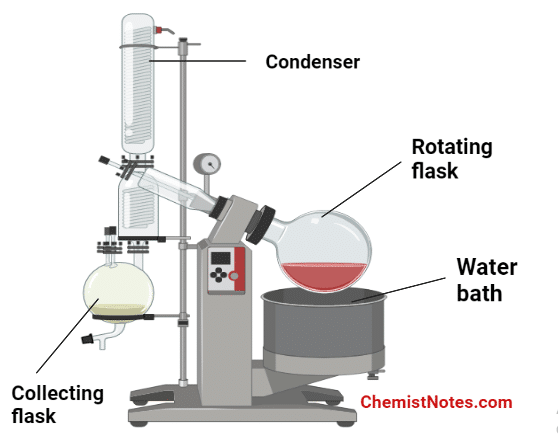

Parts of Rotary Evaporator

The rotary evaporator has the following parts and each has different significant functions, which are discussed below.

- Sample flask(Rotating flask)

- Vacuum pump

- Water bath

- Condenser

- Collecting flask

The functions of these components are described in the following section.

How does a rotary evaporator work?

As mentioned above, a rotary evaporator consists of various components viz. sample flask, vacuum pump, water bath, condenser, and collecting flask.

First of all, the sample to be purified or extracted(for example, crude plant extract) is placed in the sample flask which is also known as a rotating flask. This flask is named a rotating flask because it rotates during the operation. The vacuum pump creates a vacuum inside the flask by removing air. Therefore, air pressure is reduced inside the rotating flask. By reducing the pressure inside the flask, the boiling point of solvents decreases significantly thus it increases the rate of evaporation and separation process in low temperatures in a short duration of time without disturbing the composition of the sample.

The rotating flask is placed in the water bath and the temperature of the water bath is set up and the speed of rotation is also set up. Then, the solvents start to evaporate leaving behind the sample in the flask.

The evaporated samples are passed through the condenser where it is cooled and collected in the collecting flask.

Types of Rotary Evaporator

There are various types of rotary evaporators commercially available in the market manufactured by different companies like Buchi, Heidolph, Yamata Scientific, KNF Neuberger, LabTech, etc. The two commonly known rotating evaporators are given below.

- Vertical rotary evaporators: These are commonly used in chemistry laboratories or research labs. These are mainly used for the small volume of samples. Its main function is solvent recovery and extraction of chemicals(natural products) from the crude extract.

- Horizontal rotary evaporators: These are mainly used in large industries like chemical-producing industries, pharmaceutical industries, food industries, etc. These are mainly used for huge volumes of samples.

Heidolph rotary evaporator

Heidolph is a German company that is committed to designing and manufacturing quality instruments like rotary evaporators. Heidolph rotary evaporator is one of the best rotary evaporators which offers the following features.

- It offers the highest rate of distillation and thus it reduces the time of operation significantly.

- It has a precise temperature controller which offers users to set temperature and time accurately.

- It has a motorized lifting system that helps to move the rotating flask smoothly.

- This evaporator has been designed with multiple safety features such as automatic Shut-down of the system when the water bath becomes dry or the temperature of the system exceeds than limits.

- It offers very efficient solvent recovery of up to 100% by maintaining stable distillation conditions.

Buchi rotary evaporator

Buchi is a Switzerland company that has been providing world-class laboratory equipment for more than 80 years. Buchi rotary evaporator is one of the famous pieces of equipment all over the world which offers the following features.

- It provides evaporating flask having different capacities ranging from 50 ml to 5000 ml.

- It offers either manual or automatic lifting of the evaporating flask.

- It offers large heating temperatures ranging from 20 to 220 degrees Celsius.

- It offers mobile monitoring feature for the system which makes it easy operation for users.

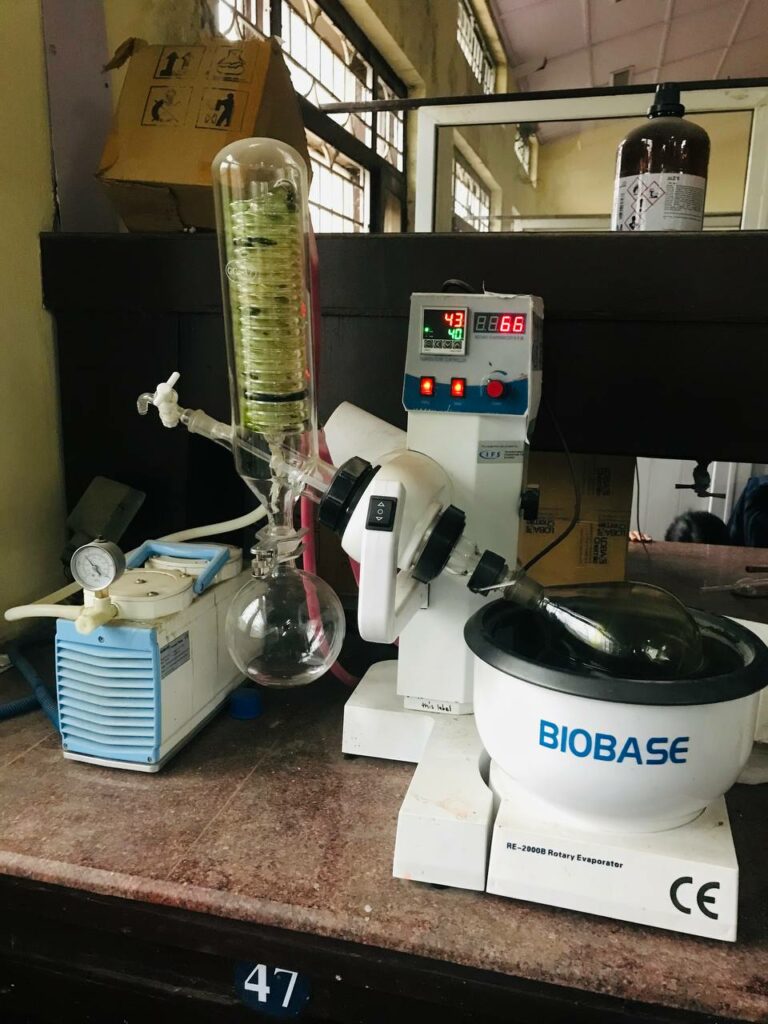

Biobase rotary evaporator

Biobase is a German company whose rotary evaporator is popular all over the world for its excellent performance. Some of the major features of a Biobase rotary evaporator are:

- It offers a step-less speed controller in the rotavap system which makes it easy to handle.

- It offers a proportional integral derivative(PID) temperature controller in the system which provides accurate and precise temperature regulation during operation.

- It offers automatic lift control for the rotating flask which makes the operation fast and easy.

- It offers a very high evaporation rate thus it reduces the operation time.

Rotary evaporator price

The price of rotary evaporators depends on the manufacturing company and models.

- The price of a Heidolph rotary evaporator ranges from 800 dollars to 40000 dollars depending on size and model.

- The price of a Buchi rotary evaporator starts from 500 dollars to 35000 dollars.

- The price of a Biobase rotary evaporator also starts from 500 dollars.

How to evaporate ethanol from extract without rotary evaporator?

If you are willing to evaporate ethanol from the extract without using a rotary evaporator, you can do it by placing the extract in the water bath at 30-40 degrees Celsius. Similarly, you can evaporate ethanol by air drying if you have enough time, just put your sample in a well-ventilated room with poor light.

Application of rotary evaporator

- This can be used in the purification of samples

- This is a very useful instrument for solvent recovery

- This is used in the purification of plant extract and essential oils from natural products.

- This is used in the distillation of complex mixtures.

Advantages of rotary evaporator over simple distillation

The major advantages of using a rotating evaporator over simple distillation apparatus are discussed below.

- Evaporation is done at reduced pressure thus the distillation is performed at a low temperature. Therefore, it is very useful for heat-sensitive compounds.

- The rate of evaporation is fast and separation can be done in a very short time.