Table of Contents

ToggleAn analytical balance is a very accurate laboratory developed to quantify an object’s mass precisely. Analytical balances are often used in labs and have a readability of up to 0.00001 grams (0.01 mg). The balance is susceptible because it provides such precise measurements. Thus, analytical balances are made with draft shields to provide protection from outside elements like air flows and dust that could impair precision.

Definition of Analytical balance

A form of balance called an analytical balance (also known as a chemical balance) is made to measure tiny masses, often under milligrams. An analytical balance with a measuring pan (0.1 mg resolution or better) is housed inside a glass enclosure with doors to prevent dust buildup and keep outside air currents from interfering with the balance’s performance. A draft shield is a common name for this enclosure.

Principle of analytical balance

The “magnetic force restoration” theory underlies the operation of analytical balance. It is an electromagnetic balance that uses an electromagnet to determine an object’s mass. The force acting downward on the balancing pan is what is measured by these balances rather than the mass itself.

Range of analytical balance

An extremely sensitive laboratory tool known as an analytical balance can precisely measure mass down to the sub-milligram range. The weighing capacity of analytical balances is between 100 and 500 g, and their readability ranges from 0.1 mg to 0.001 mg.

Calibration of analytical balance

To acquire accurate weighing findings, calibration, which is defined as an association between measurements, is necessary. To verify that they are accurately displaying the proper measurement in accordance with their country’s norms, balances are calibrated.

Due to their unique mechanism that can detect even the smallest changes in mass, analytical balances provide extremely accurate results. To protect them from outside influences that might interfere with their operation, they are produced in clear boxes with doors. As a result, they must be handled in designated rooms with carefully regulated ambient conditions due to the requirement for extremely precise measurements.

Types of analytical balance

Analytical balances are made to quantify tiny masses ranging from 320g to less than a milligram. They should be handled carefully because they are delicate pieces of machinery. The following are the primary types of laboratory balances (the masses listed are simply approximate values):

• Top-pan balance (200g – 0.001g)

• Analytical balance (320g – 0.0001g)

• Microbalance (6g – 0.000001g)

• Ultra fine balance (6g – 0.0000001g)

How to operate analytical balance?

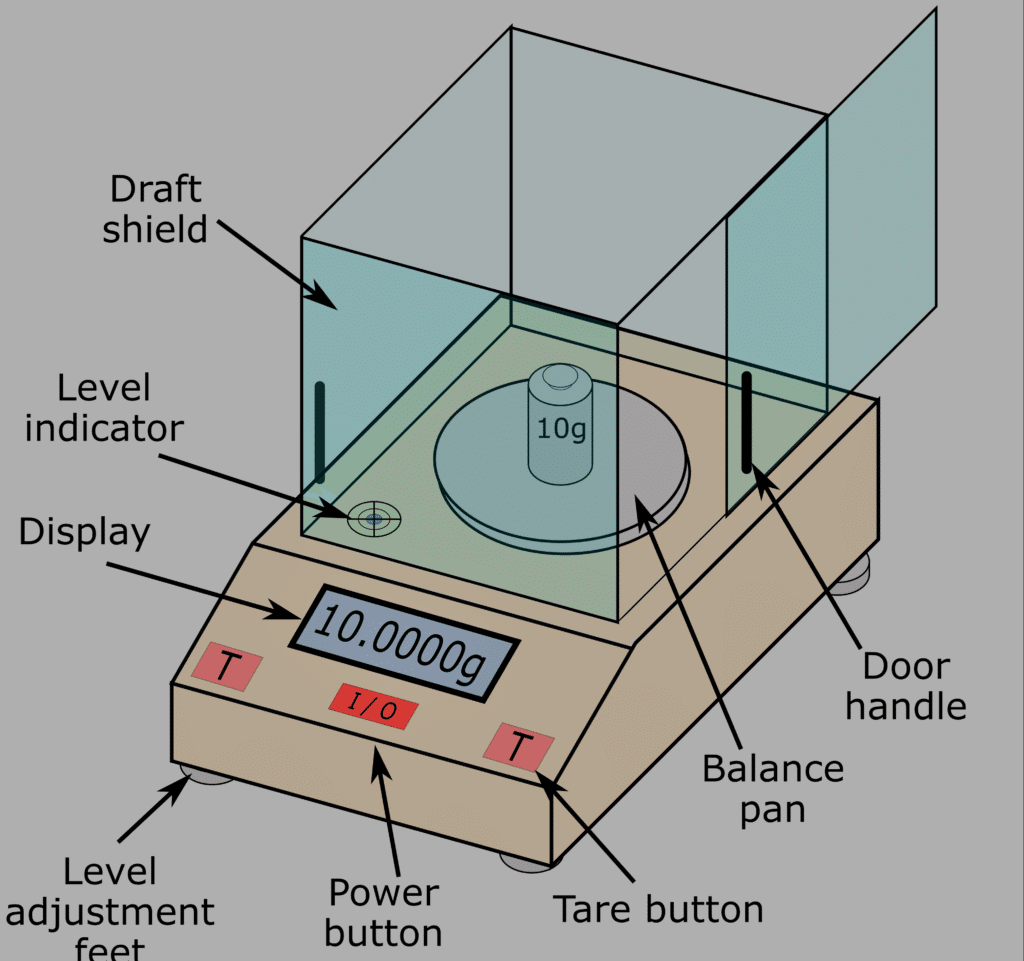

. The level of balance is checked first by a level indicator to determine whether the balance is level. Then the level is adjusted, typically by rotating the feet, if the bubble is not in the center until it is in the center of the inner circle.

• Then we have to ensure the door is shut or not and the balance is turned on. When the mass reads 0.0000 g, the “Tare” button is pressed, and 5–10 seconds of waiting for a “*” or other similar sign to appear in the upper left/right corner of the display.

• The door is unlocked and we have to insert a weight boat, weight paper, or another object on the balance pan’s middle (ideally with tweezers or similar).

• Then the door is closed and watched for the digital reading to stabilize (‘*’).

The “TARE” button is pressed to reset the mass to zero if you don’t want to include the mass of the container in your measurement, then the container from the balance is removed, and the object to be weighed is added. We have to avoid putting things in the balance pan because doing so can contaminate the equilibrium.

• The container is kept back in balance and the mass reading 5 to 10 seconds (up to a minute) to set.

Price of analytical balance

The Sartorius Internal Analytical Balances, Accuracy: 0.1 Mg, Capacity: 220 G

Costs generally for ₹ 95,000

The Sartorius Professional Weighing System Entris II Analytical Balance, 220g, 0.0001g New Entris Model BCE 224i-1S Internal Cal. 220 Pounds. $2,467.50$2,467.50.

Parts of analytical balance

Various parts of analytical balance are discussed below:

- Balance pan

This is the surface where the item to be weighed is set. To avoid contaminating the object being weighed, it is often composed of a non-reactive material like stainless steel.

2. Weighing pan

This is the area where the balancing pan is placed. It is often constructed of strong, solid material, such as metal or granite, and is intended to reduce vibrations and other outside influences that can impair the measurement’s accuracy.

3. Load cell

A force is transformed into an electrical signal using this apparatus. In an analytical balance, the load cell, which measures the force applied by the object being weighed, is situated beneath the weighing platform.

4. Keyboard or control panel

The area of the balance where orders can be entered and the balance’s operations are controlled.

5. Draft shield

This transparent enclosure shields the balance from air currents and other outside forces that can skew the measurement’s accuracy. It is placed around the balance pan.

Uses of analytical balance

Analytical balances are used in a variety of applications:

- Sample preparation

- Formulation/Recipe Calculation

- Checkweighing

- Interval weighing

- Pipette testing

- Animal weighing

- Differential weighing

- Density analysis/determination

- Piece counting