Table of Contents

ToggleSolid phase microextraction (SPME) has been introduced as a modern alternative to current sample preparation techniques, which eliminates the need for organic solvents, significantly reduces analysis time, and allows for easy automation of the sample preparation step. It can be regarded as a green extraction technique because it significantly reduces or eliminates the solvent required for sample preparation.

Solid phase microextraction

Solid phase microextraction is a quick and easy sample preparation technique that extracts organic analytes from a matrix onto a stationary phase, similar to solid phase extraction. This is a fast and solvent-free or very small amount of solvent used, adsorption/desorption technique.

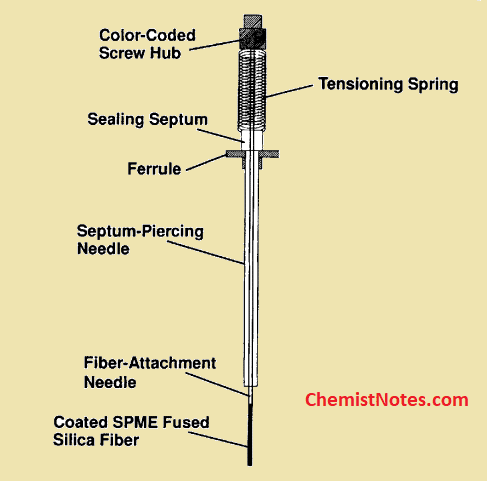

SPME uses a small amount of extraction phase, known as coating, that is immobilized on a solid support which may be fiber or arrow. When it is exposed to the sample matrix, analytes are extracted onto the coating.

The typical SPME instrument is shown below:

Solid phase microextraction principle

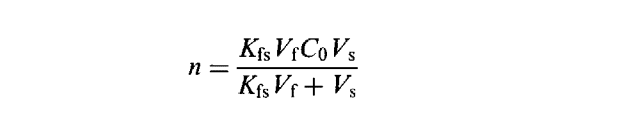

SPME is a technique based on the principle of partition mechanism and the equilibrium of the analyte is established between the sample matrix and the polymeric phase on the fiber. The amount of analyte extracted by the coated surface is given by the Nernst distribution law. For a liquid polymeric coating( PDMS), the amount of analyte absorbed by the coating at equilibrium is directly proportional to the concentration of the analyte in the sample. This can be related by using the following equation.

Where n= mass of analyte adsorbed by the coating

Vf= volume of coating

Vs= volume of sample

K= partition coefficient of analyte between coating and sample

Sample preparation by SPME consists of two processes, sample extraction, and sample desorption. In the extraction step, the analyte is adsorbed onto the surface of a coated silica fiber. After equilibrium is reached, the fiber is withdrawn into the needle, and the needle is withdrawn from the septum.

In the desorption process, the needle is inserted into the injection port of the analytical instrument, the fiber is exposed, and the target analytes are desorbed to the instrument for analysis.

SPME is a modification of solid phase extraction in which a solid-phase column has been replaced by a microliter syringe-like device with a hollow needle and a plunger to which, a fused silica fiber coated with a suitable stationary polymer is attached. The principle applies the same as that of Solid phase extraction but the mode of operation is different.

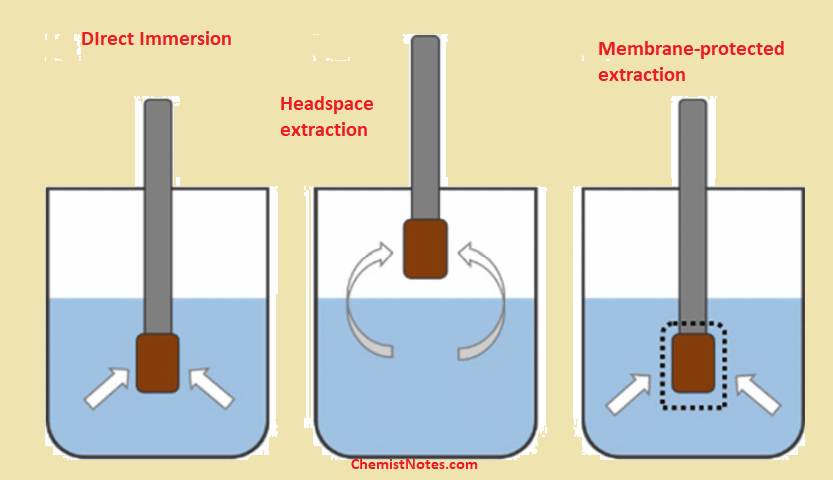

There are three basic modes in SPME.

- Direct immersion(DC)

- Headspace extraction(HS)

- Membrane-protected extraction.

Direct immersion

- In direct immersion mode, the coated fiber is immersed in the sample solution and the analytes are transferred directly from the sample matrix to the coating.

- The mass transfer of the analytes from the sample to the coating in the extraction process can be accelerated by agitating the sample, which ultimately speeds up the extraction.

- This mode is useful for semi-volatile analytes.

Headspace extraction

- In the headspace extraction mode, the fiber is placed in the headspace above the sample matrix.

- analytes are extracted from the gas phase equilibrated with the sample.

- This modification is designed to safeguard the fiber from the negative effects of non-volatile, high molecular weight substances present in the sample matrix.

- This method is useful for volatile compounds in the sample.

Membrane-protected extraction

- For the analysis of non-volatile compounds with the inference of macromolecules, both direct extraction and headspace extraction are inapplicable.

- In such a case, membrane-coated extraction will be the best choice.

- With the protection of the selective-access membrane, the unwanted macromolecules can be hindered away and the coating will be free from pollution or contamination.

Solid phase microextraction procedure

In the first step, the coating is expressed to the sample to selectively extract the analytes by the strong affinity of the analytes and the extraction phase. Then, all the components extracted by the coating are desorbed into an analytical instrument.

For SPME, the fiber is inserted into the vial containing the sample(solution or air) (time up to 20 mins). The fiber is withdrawn back from the sample vial. The SPME device is inserted into the injector of GC for a specified time ( not more than 2 mins). The heat of the injector desorbs the compounds from the fiber.

SPME is applied to both gas chromatography and liquid chromatographic separation. It possesses two distinct steps.

- Adsorption of a compound onto a suitably coated silica fiber (as stationary phase): The choice of the sorbent is essential so that it must have a strong affinity for the target analyte compounds. For example, the fused-silica polydimethylsiloxane(PDMS)-coated fiber is one of the most commonly used sorbents.

- Desorption of sample into a gas chromatogram: As the normal method of introduction of the sample into a gas chromatograph is via syringe, solid phase microextraction is the most useful for gas chromatography. But it has been used for HPLC also(need mobile phase). In gas chromatography, desorption occurs in the hot injector of the GC. It is common to find that no solvent peaks should be present in the GC.

Solid phase microextraction applications

SPME is an effective and reliable tool for qualitative and quantitative analysis of many different compounds.

- it can be used for the analysis of environmental pollutants including volatile organic compounds, semi-volatile organic compounds, pesticides, herbicides, etc. (Environmental analysis)

- it has been used for the analysis of forensic drugs, volatile to non-volatile drugs.(Drug analysis)

- SPME can be used as an air sampler for a broad range of analytes.

- This technique will find use in routine water analysis due to its ease of use and potential cost savings.

- It is used in food and fragrance analyses.

- It is used to study the variety of plasticizers and other additives in lamination films.

- It is also used in the sample preparation of biomedical analyses.

Advantages of solid phase microextraction

- It is a simple and faster process.

- it is effective for analyses with a small sample amount.

- SPME extractions and desorptions can be fully automated i.e. automation are possible.

- The absence of solvent makes it environmentally friendly.

- The polymeric phase is cleaned during the desorption of the analyte, and it is ready for the next use.

Disadvantages of Solid phase microextraction

- Relatively expensive due to the cost of fiber (approx $108).

- The polymer coating is fragile, easily broken, and has a limited lifetime.

- It has reduced concentration ability due to the small volume of polymer coating on the fiber.