Table of Contents

ToggleMicrowave assisted extraction is a green approach to an analytical technique in which microwave radiation of frequency ranging from 0.915 to 2.45 GHz is used for the extraction of chemical compounds, especially from plant materials. This technique has become a new tool for organic synthesis and in the extraction of biological matrices for the preparation of analytical samples.

Microwave assisted extraction

Microwave-assisted extraction is a process of using microwave energy to heat solvents in contact with a sample in order to separate analytes from the sample matrix into the solvent. This technique is used for the extraction of organic compounds from solid samples. Previously microwave ovens are used for the digestion of samples for metal analysis.

All microwaves, whether they are found in the home or the laboratory, operate at one frequency i.e 2.45 GHz, even though in practice, the microwave region exists at frequencies of 100 GHz to 300 MHz(or wavelengths from 0.3mm to 1m).

Selection of solvent

The selection of an organic solvent for microwave-assisted extraction(MAE) is essential, the solvent must be able to absorb microwave radiation and thereby becomes hot. The ability of an organic solvent to be useful for MAE can be assessed in terms of its dielectric constant, the larger the value of the dielectric constant, the better the organic solvent’s ability to become hot.

Common organic solvents used in MAE are acetone, Acetonitrile, Dichloromethane, Hexane, methanol, etc.

Microwave assisted extraction principle

The fundamentals of the microwave extraction (MAE) process are distinct from those of traditional methods (solid-liquid or simple extraction) since electromagnetic waves cause changes in the cell structure that lead to extraction.

When the microwave is passed through the materials, molecular interaction takes place with the wave. Therefore, microwave energy is converted into thermal energy that helps in the mass transfer from the inside to the outside of the plant cell. In this way, bioactive compounds can be extracted by using microwave energy.

The traditional methods of solvent extraction of plant materials rely on the proper selection of solvents and the application of heat or/and agitation to improve mass transfer and increase the solubility of the desired compounds. That’s why, this new method of extraction, microwave-assisted extraction method with shortened extraction time, reduced solvent consumption, increased pollution prevention, and special care for thermolabile constituents have gained attention.

Microwave-assisted extraction procedure

Two approaches are used for devices for MAE.

- Open MAE system(Atmospheric)

- Closed MAE system(Pressurized)

Open MAE system

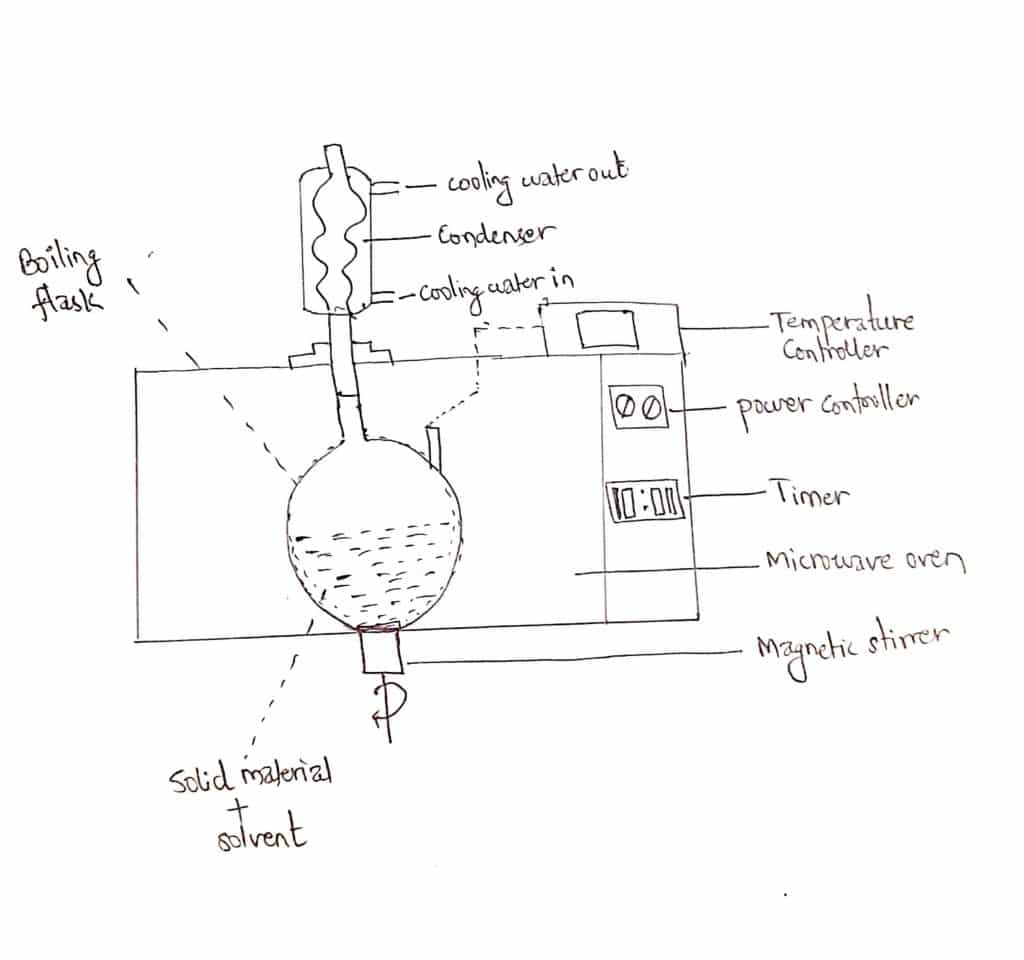

In the open MAE system, the sample is located in an open vessel to which an appropriate organic solvent is added. The microwave generated from the magnetron is directed by the waveguide onto the sample/solvent system, thus causing the solvent to boil and rise up within the vessel.

The hot solvent then comes into contact with a water-cooled reflux condenser. This causes the solvent to condense and return to the vessel. This process is repeated for a short period of time so enabling organic compounds to be desorbed from the sample matrix into the organic solvent.

Typical operating conditions for atmospheric MAE are as follows:

- Temperature up to the boiling point of the solvent.

- Extraction times, 5-20 min

- Power setting of 100% at 300 W.

As the extraction vessels are open to the atmosphere, minimal cooling time is required post-extraction prior to handling the vessels.

Closed MAE system

In the closed MAE system, microwaves enter the cavity( the oven), and are dispersed by a mode stirrer. The mode stirrer allows an even distribution of microwaves within the cavity. The other major difference in the pressurized MAE system is that the sample and solvent are located within the sealed vessel which is usually made of microwave-transparent materials such as poly(ether imide) or trifluoromethoxy polymers operating conditions for pressured MAE are as follows:

- Pressure < 200 psi

- The temperature is within the range of 110-145 oC.

- Power setting of 100% at 900 W.

Application of microwave assisted extraction

- Closed vessel techniques of MAE are used for the extraction of terpenes.

- Extraction of imidazolinone herbicides and sulphonylurea herbicides has been reported.

- Extraction of fungicides i.e hexaconzole via MAE from weathered soil can also be done.

- Extraction of additives polypropylene and polyethylene in the field of polymer research.

- The food processing industry uses MAE for the processing of vitamins in foodstuffs.

- Determination of various metals like Pb, Zn, and Cu from soils using sequential microwave extraction procedures has been reported.

Advantages of microwave assisted extraction

- In MAE, extract multiple samples simultaneously using a minimal organic solvent.

- Reduction in extraction time.

- Improved yield.

- Better accuracy

- Suitable for thermolabile substances.

The main disadvantage of this technique is the relatively high capital cost and maintenance of the system for effective operation. Similarly, when the target compounds or solvents are nonpolar or volatile, the efficacy of microwaves can be poor, and using high temperatures can cause heat-sensitive bioactive compounds to degrade.