Table of Contents

TogglePaper and Pulp are the latest updated topics in the applied chemistry syllabus for the 12th grade, which is a very important topic to learn. The cellulose fibers in wood, fiber crops, scrap paper, and rags are separated chemically or mechanically to create pulp, a lignocellulosic fibrous substance. Pulp is the main raw material used in the industrial manufacturing of various paper products, along with water and other chemical or plant-based additives.

What are Paper and Pulp?

Paper and Pulp, often known as pulp, are fibrous substances that are the main raw materials for the production of paper, manufactured from plant fiber using various pulp processing techniques. Cellulose, hemicellulose, lignin, pigment, resin, pectin, and ash are a few of the main components of pulp.

Source: http://Robert C. Williams Museum of Papermaking

Raw materials used

Making pulp from wood chips is the first stage in a standard paper production process. In North America, softwoods with thin, robust, and elastic fibers, including spruce and pine, are the most commonly utilized species. In general, there are two ways to make pulp, the primary component of paper: chemical pulping or mechanical pulping. More than 90% of the pulp manufactured is made from wood, which is the primary fibrous raw material utilized in this process. Non-wood fibers have a significant role as a source of raw materials, particularly in developing nations.

Sources of raw materials

A vast range of materials, including cotton, wheat straw, sugar cane waste, flax, bamboo, wood, linen rags, and hemp, have been used to make paper throughout history. Whatever the source, fiber is required to manufacture paper.

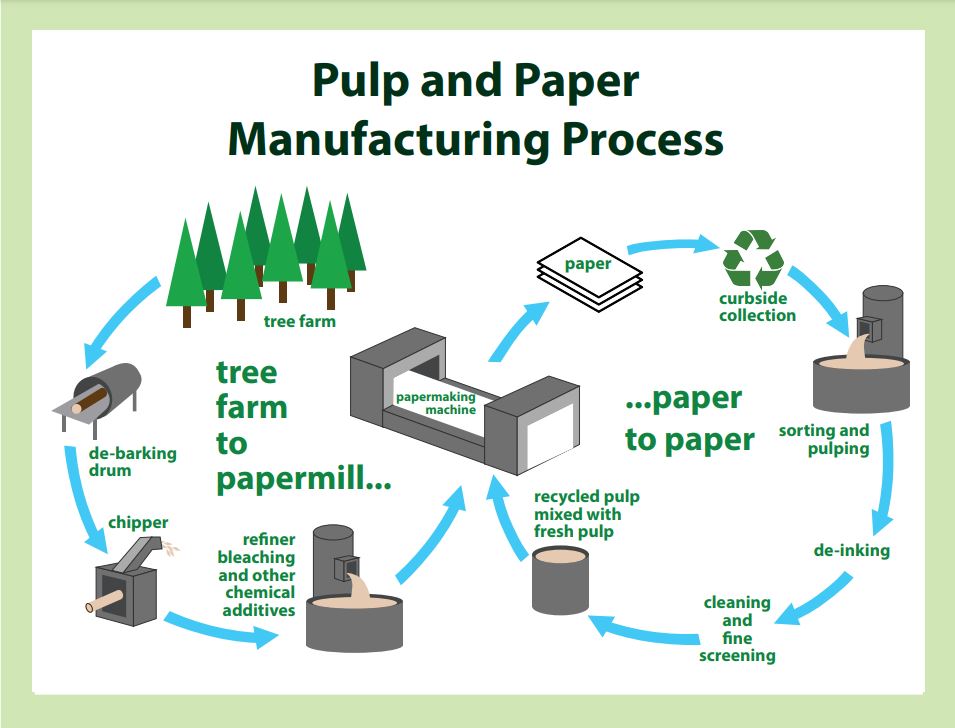

Stages in production of paper

Typical mechanized paper production involves two main processes: the treatment of the raw material, which includes converting the chip into pulp, washing and bleaching, refining, beating, sizing, coloring the fibers, and later forming paper sheets in a Fourdrinier machine.

- The fibers are separated and cleaned through the process of pulping.

- Following the pulping stages comes the refining process.

- The creation of a fine fiber combination by dilution.

- fiber formation on a tiny screen.

- Pressurization increases the density of the materials.

Let’s go into detail about the production of paper:

The extraction of the fibrous raw material into a pulp and the subsequent conversion of the pulp into paper are the two main steps in the production of paper. Both mechanical and chemical processes can be used to produce pulp. The pulp is then retouched and thus further processed, depending on the kind and quality of paper needed for processing. The pulp is made of wood or other lignocellulosic materials that have been mechanically or chemically split. The released, detachable fibers can be disseminated in water and transformed into a web of woven pulp. By applying mechanical force to the chips, pulping breaks down the connections between the fibers.

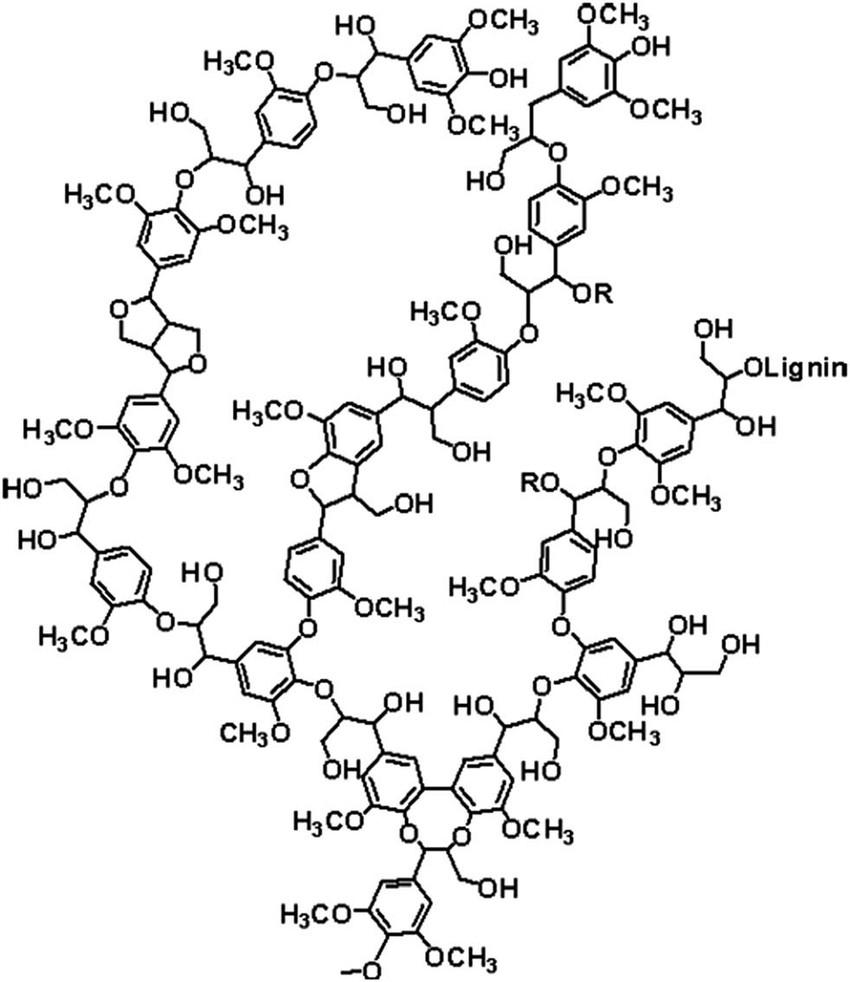

This device employs electricity as its main energy source to create mechanical capabilities. The goal of mechanical pulping is to maintain the essential lignin component to ensure that the pulp’s high potential may be achieved with enough strength and durability. qualities of illumination. Chemical heat and pressure are used in chemical pulping to break down the chemicals.

Lignin and other elements of the inter-fiber matrix material are also broken down during this process. The formation of hydrogen, enables the fibers to bind together during the papermaking process and linkages between the surfaces of their cellulose. In this instance, kraft and sulfite are used to create chemical pulps.

- Preparation of raw materials:

- To get rid of any impurities, such as plastics or metals, raw materials like wood chips, recycled paper, or other materials are gathered, sorted, and processed. Following that, the raw materials are cleaned and debarked.

- Pulping:

- To create pulp, the basic ingredients are minced into tiny bits and combined with water and chemicals. The pulp is then heated and agitated to dissolve the fibers and get rid of any contaminants that are still present.

- Refining:

- To enhance the fiber quality and make them more suited for papermaking, the pulp is further refined. The pulp is refined by being run through many screens and filters.

- Forming:

- Water is removed when the pulp is put over a wire mesh filter. After being compressed to force out more water, the residual fibers form a wet mat.

- Pressing:

- To extract even more water and condense the fibers, the wet mat is forced between rollers.

- Drying:

- The paper is dried either by hanging it on a drying rack or by running it through a series of heated rollers.

- Finishing:

- In order to enhance the paper’s qualities, such as brightness, smoothness, or water resistance, the paper is cut into the necessary size and shape and may be coated or treated with chemicals.

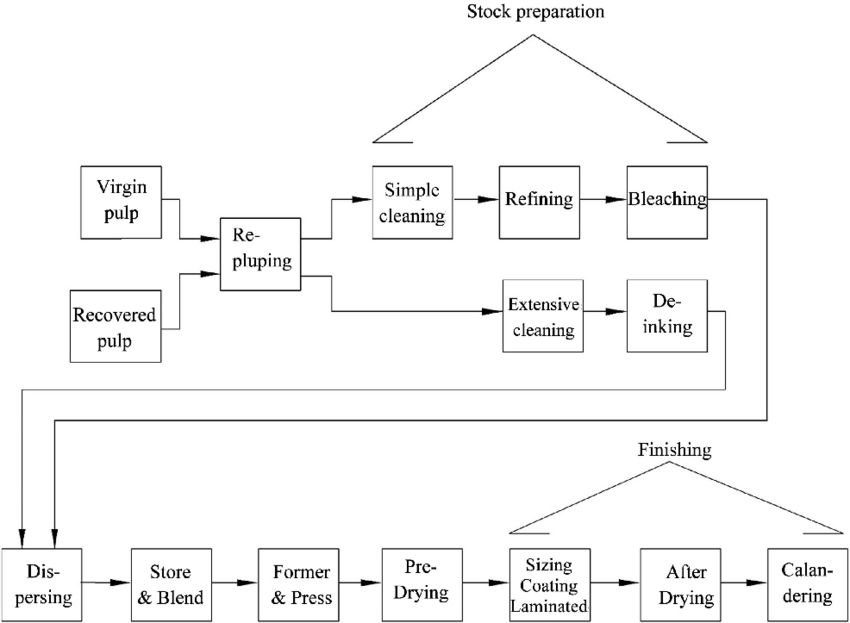

Flow sheet diagram for paper production

Source: https://www.researchgate.net/figure/Process-flow-diagram-of-paper-production_fig2_322308391