Table of Contents

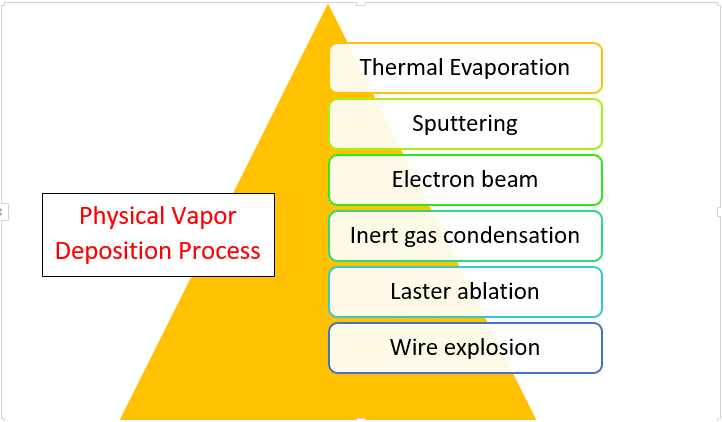

TogglePhysical vapor deposition (PVD) is a dynamic bottom-up-based synthesis technique capable of producing thin film materials at a nanometre scale (1-100nm). In physical vapor deposition, the material is heated above its melting point to generate vapors, which are then deposited on the target surface. It involves the

generation of vapor phase either via evaporation, sputtering, laser ablation, or by using an ion beam or electron beam.

Physical Vapor Deposition Process

Some of the physical vapor deposition processes are:

Thermal evaporation

This method involves heating a source above its melting point in order to extract atoms from it. Using physical vapor deposition techniques, a single element with a low melting point, often a metal, can be converted into nanomaterials. However, it is challenging to deposit a consistent combination of two distinct materials because of the variation in melting points. Both solids and liquids can evaporate and produce vapors. The solid particles are produced by the nucleation and condensation of the saturated vapor during the cooling process.

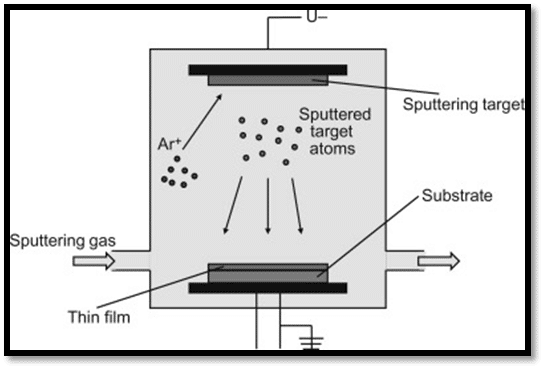

Physical vapor deposition sputtering

Sputtering is a process of depositing materials of high melting points via ejecting atoms by the bombardment of source material with energetic ions and leads to the generation of nanomaterials. In comparison to other evaporation techniques, sputtering enhances the stoichiometric control of the film. Moreover, high melting point refractory materials such as ceramics, which are impossible to generate a vapor phase by thermal evaporation technique, can be deposited by sputtering.

The main drawback of this method is the deposition of even impurities that is present in target materials. As a result, sputtered films are more susceptible to contamination as compared to evaporated films.

Electron beam physical vapor deposition

Electron beam evaporation is a physical vapor deposition method that leads to film deposition. In this method, a high-energy electron beam generated from a source (usually filament) is focused on a target. Atoms are evaporated from the target surface as these electron beams strike it, transferring energy from the electron beam to the surface. Then, in a vacuum environment, these vapors move and deposit themselves on the substrate that is situated above the target. Vacuum conditions facilitate efficient material deposition by increasing the mean free path of vapor.

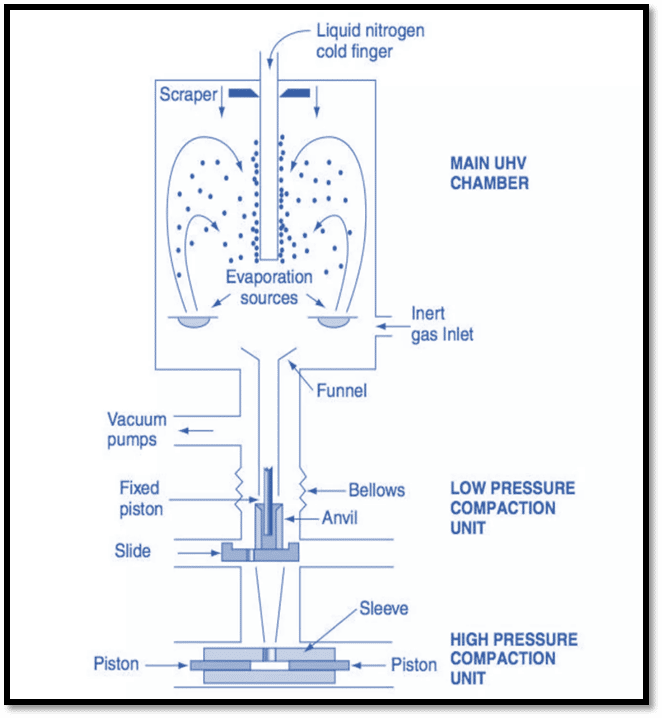

Inert gas condensation

Inert gas condensation with thermal evaporation is commonly used to synthesize metallic and

metal oxide nanopowders with a well-defined and narrow size distribution. In this method, an inert gas, usually helium, at low pressure and a high vacuum (UHV) is used to evaporate a metal. When evaporating particles collide with inert gas molecules (helium), they lose kinetic energy, coalescing to form a cluster of nanoparticles. The particles are deposited on a cold finger which is then removed by a scraper and collected into the funnel followed by its transportation to an in situ compaction device that prevents them from agglomeration. To stop the metallic nanoparticles from oxidizing, the scraping and consolidation of the particles are done under an ultra-high vacuum.

The size of synthesized particles depends on the reaction conditions like inert gas pressure, gas composition, rate of evaporation, and so on. Additionally, particle nucleation, coalescence, and growth during condensation are key factors for the formation of small-size particles in large numbers. One of the main advantages of this technique is that it exhibits a higher production rate of about 60 g/h and a yield of 75%.

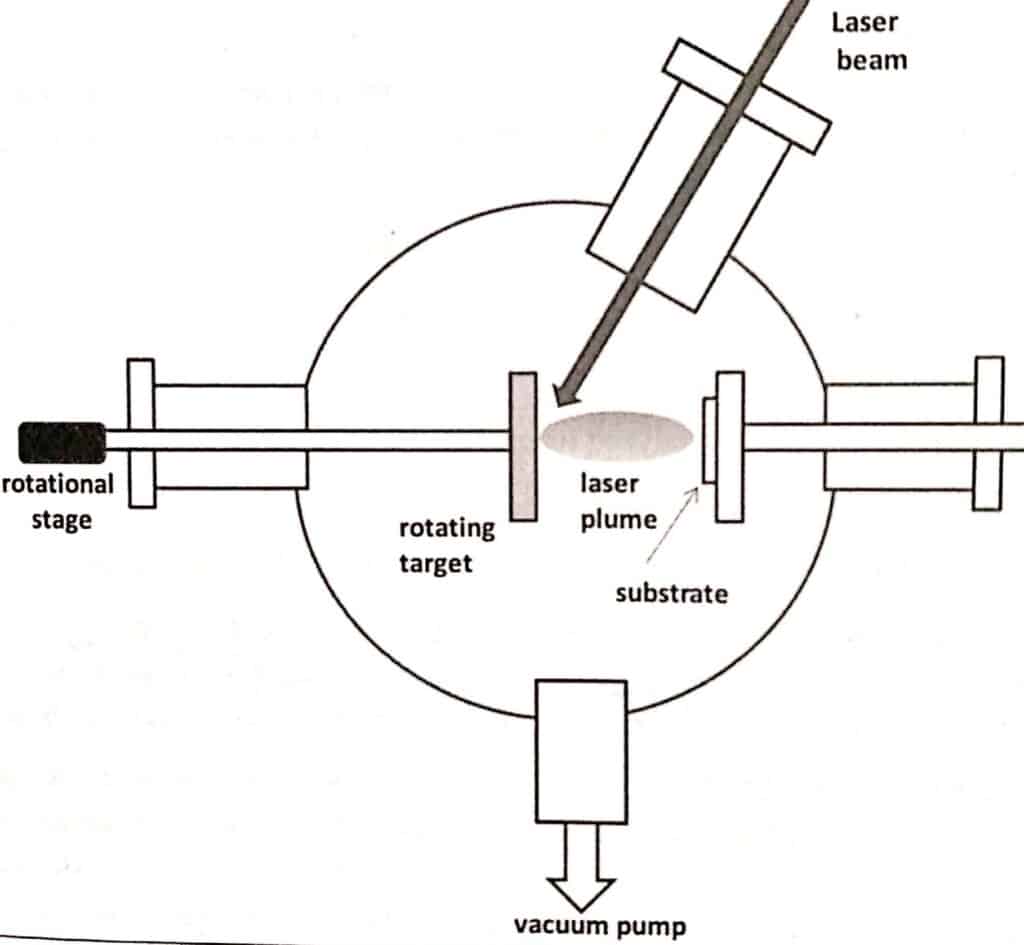

Laser ablation

Laser ablation is another physical vapor deposition method that offers greater evaporation control by uniformly evaporating the components of multicomponent materials in a very short span of time. In this method, high intensity focused pulse laser beam is incident on the surface of target materials leading to the evaporation of atoms or clusters of atoms. The term “ablation rate” often refers to the total mass removed/ablated from the target by each laser pulse.

Laser ablation in combination with ion gas condensation is an intriguing technique to synthesize larger amounts of multicomponent nanocrystalline materials. Atoms that have been abated by a laser pulse tend to collide with helium gas during this process, rapidly losing their kinetic energy. Eventually, they condense into a cloud of tiny nanocrystalline clusters.

Moreover, the rate of nanoparticle synthesis varies with the rate of ablation, the nature of the inert gas, the nature of the material, and so on. Many researches regarding the synthesis of nanoparticles using laser ablation with inert gas condensation has been reported.

Wire explosion

A physical vapor deposition method called “wire explosion” uses high voltage to explode metallic wires. Nanoparticles are synthesized by the condensation of gaseous atoms and molecules formed inside the chamber. Different derivatives of metallic nanoparticles, such as nitrides, oxides, etc., can be produced inside the chamber by properly controlling the environment, or the composition and chemistry, of the vacuum.

Physical vapor deposition vs Chemical vapor deposition

FAQs

What is physical vapor deposition?

Physical vapor deposition is a bottom-up based nanosynthetic technique that involves the generation of vapors either by evaporation, sputtering, laser ablation, or an ion beam or electron beam so as to produce thin film materials at a nanometre scale.

Physical vapor deposition video

References

- Yap, Y.K. (2012). Physical Vapor Deposition. In: Bhushan, B. (eds) Encyclopedia of Nanotechnology. Springer, Dordrecht. https://doi.org/10.1007/978-90-481-9751-4_362