Table of Contents

ToggleAn autoclave machine is a device that uses pressurized steam to destroy dangerous germs, bacteria, viruses, fungi, and spores on objects that are placed inside a pressure vessel. For a specific period of time, the items are heated to the proper sterilizing temperature.

What is an autoclave machine?

An Autoclave machine is a device or just like a pressure cooker used to sterile lab goods, objects, and even a variety of media, etc. present from the contamination. Both a pressure cooker and a very simple autoclave use the force of steam to kill bacteria, spores, and other types of germs that are resistant to boiling water and powerful detergents.

History of autoclave

Charles Chamberland is known to have invented the autoclave sterilizer in 1879. During that time, scientists began to comprehend the benefits of sterile surgery, and medical professionals need a more dependable sterilizing technique than an open flame.

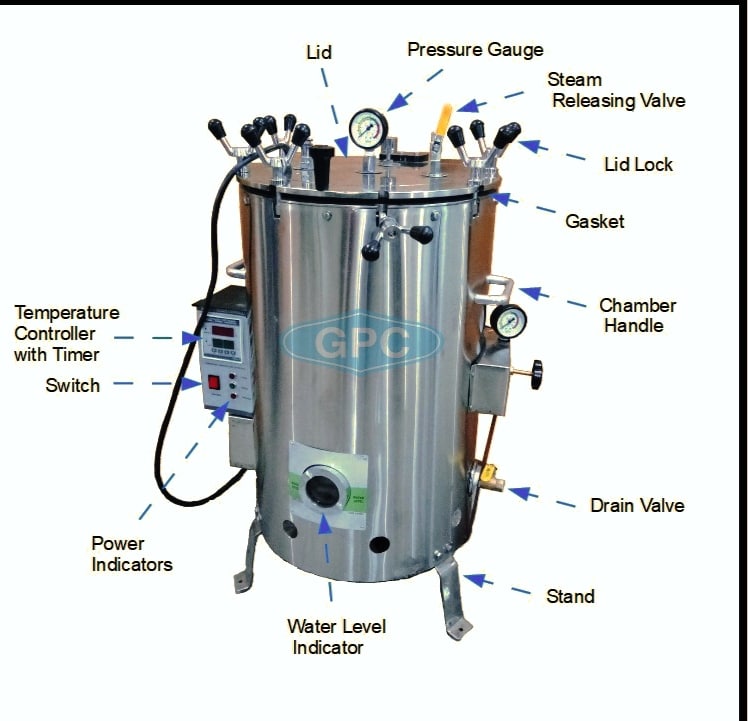

Parts of the autoclave machine

Different parts of the autoclave machine are discussed below:

- Power cord

- Power cables are the cords that electric autoclaves, which are powered by electricity, require. Electricity may be transmitted to the autoclave using this cable from the plug.

- Timer

- Most power-powered autoclaves contain buttons or timers for setting the time. The duration of the sterilizing process can be set with this button.

You can modify the length of time the sterilizing procedure needs to last based on your requirements by pressing the timer button.

- Temperature

- The sterilization temperature is set using the autoclave’s temperature control button. When the temperature reaches the predetermined point, pressing this button instructs the autoclave to begin sterilizing.

- Pressure gauge

- The pressure of the device increases when the autoclave is in use. Thus, a pressure regulator is required for an autoclave in order to regulate the amount of steam produced inside the autoclave during sterilization.

- Life lock

- The autoclave cover is secured by the safety screw. This coupler’s particular construction prevents the autoclave lid from opening, leaking, or becoming loose. The entire top of the autoclave is covered in many safety screws.

- Steam releasing valve

- The valve that releases steam from an autoclave is one of its minor components. This two-part valve’s most crucial function is to release steam pressure during the sterilization process. In cases of excess or excessive pressure, the steam relief valve can also be utilized to reduce the pressure.

- Heating element

- The hot plate or heating element is positioned at the bottom of the pressure vessel.

- An autoclave’s hot plate converts electricity into heat in an autoclave is powered by electricity.

With the help of an electric current, the copper wire coils or loops that make up this hot plate can heat up.

- Lid

- There are two different kinds of autoclaves, those that open from the front and those that open from the top. An autoclave’s lid or cover acts as a cover to protect the contents from harm and to ensure that the sterilization process goes as smoothly as possible.

- Water level indicator

- The area of the autoclave enables you to monitor the water level inside the device while it is sterilizing.

We should be aware of the following general information regarding an autoclave. There are pieces unique to each type of autoclave.

How to use an autoclave machine?

The main idea behind an autoclave is that by using a powerful vacuum system to remove the air from a sealed chamber, they may increase the pressure inside their vessel and produce the ideal conditions for quickly and efficiently obtaining sterility. Increased pressure also makes it possible for water to boil at a greater temperature, allowing the machine to use steam that is much hotter than 100 degrees Celsius—specifically, between 121 and 134 degrees.

- The goods are kept in the autoclave which is to be sterilized inside. The entrance is secured.

- Air is removed from the chamber using a vacuum pump.

- The temperature is at the proper setting.

- Microbes and bacteria are destroyed by steam.

- The door is opened, the steam is let out, and the equipment is now usable.

Industrial autoclave machine

For a variety of procedures in numerous sectors, industrial autoclaves enable high temperatures and pressures. Although they are typically used to sterilize infectious trash, these devices can also be used to cure and strengthen composite parts that must resist challenging conditions and/or heavy use.

Types of autoclave machine

There are various types of autoclave machines but, they are generally classified into two major types on a different basis.

On the basis of product size:

- Class N types autoclave machine: Naked Solid Products” is what the letter “N” stands for. As a result, these autoclaves are unable to sterilize textiles, porous loads, hollow objects, or even products in pouches because the cycles do not meet the requirements to pass particular physical tests.

2. Class B types

“Big small sterilizers” is what the letter “B” stands for since these little devices pack a powerful punch. A Class B autoclave has the ability to sterilize any kind of load. Included in this are porous materials, goods packaged in pouches, fabrics, and hollow objects like wands, turbines, and tips.

3. Class S types

The decontamination of single and double-wrapped devices, porous materials, and small parts is ensured by Class S steam sterilization. Even basic hollow body tools with hinges can be sterilized using the MELAG high-performance vacuum pump (scissors, clamps).

On the basis of shape :

- Vertical

The cylindrical-shaped vertical autoclave sometimes referred to as steam sterilizers and top-loading sterilizers is a sterilizing device. These devices assist in the sterilization of many items, including surgical tools and medical equipment.

2. Horizontal

A horizontal autoclave is a floor-mounted unit that includes a sterilization chamber, boiler, piping and fitting, sensors, and control panel. All of these parts and components are joined and fitted on a stand. To ensure a corrosion-resistant surface, our horizontal autoclave units are constructed of stainless steel.

3. Pressure cooker

Large saucepans that use steam under pressure to swiftly cook food are essentially what pressure cookers are. On the other hand, an autoclave is nothing more than a sizable pressure cooker that raises the temperature of the steam inside the chamber above the water’s regular boiling point.

How much is an autoclave machine?

0.22 MPa is the pressure. Temperature range for sterilization: 122 to 258 degrees Fahrenheit. Cost: $100 – $1779. Features consist of: stainless steel that is Class II acid-proof is used.

Considering all the different ways this technology is applied and used, an autoclave’s price might vary substantially. Compared to autoclaves you may find in a hospital or dentist’s office, industrial and pharmaceutical autoclaves are made specifically for their intended function and are therefore likely to cost more.

Autoclave machine price

Typically, an autoclave machine costs between INR 10,000 and INR 1.5 lakh in India.

60 Litre Top Loader: 13.8” x 24.4” deep ($18,000 – $40,000)

100 Litre Top Loader: 19.5” x 21.1” deep ($25,000 – $44,000)

150 Litre Top Loader: 19.5″ x 28.4″ deep ($27,000 to $46,000)

Autoclave machine for Sterilisation

Sterilization of surgical tools, lab equipment, pharmaceutical goods, and other materials is accomplished using an autoclave. It has the ability to sterilize hollow objects, liquids, solids, and devices of all sizes and shapes. The size, design, and functioning of autoclaves vary. Both a pressure cooker and a very simple autoclave employ the power of steam to kill bacteria, spores, and germs that are resistant to boiling water and powerful detergents.

Function of Autoclave

Glassware that can trap air and/or needs to be sterilized upright.

wrapped, airtight products for dry storage.

tip boxes for pipetting.

Decontamination of sharp objects.

(in containers for collections)

Decontamination of biohazard material in autoclave bags; may be moist or dry.