Table of Contents

ToggleNanoindentation is one of the most common approaches used to measure the mechanical properties; hardness and elastic modulus of nanomaterials. It is a relatively new technique that observes the stress-strain behavior of nanomaterials when a nanoindenter is pressed against the materials under investigation.

In nanomaterial research besides measuring surface makeup (topography), surface micro properties and composition, measurement of mechanical property is equally important. Typically, scanning force microscope (SFM) tips are utilized for both the indentation and the subsequent imaging of the sample surface. The force (stress) exerted on the nanomaterial (sample under investigation) determines the depth of indentation, which is then measured. The loading-unloading curves can be used to calculate the mechanical properties, including the elastic constants.

Nanoindentation Principle

The principle of nanoindentation is similar to other indentation hardness testers, in which an indentor is

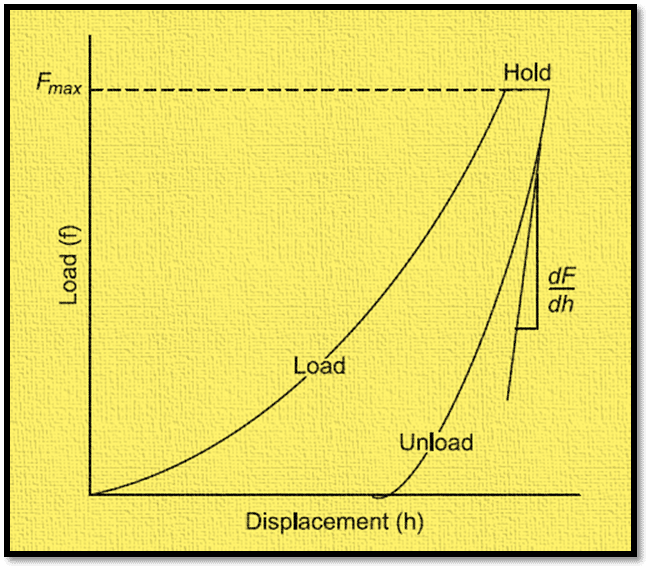

forced into the material being tested, forming an indent. In nanoindentation testing, stress or load (usually force) is applied to the sample using a nanoindenter and force applied (F) is measured as a function of depth/height of indendtation. The ratio of the load and the area of contact between the sample and the indenter is used to determine the hardness. A depth-sensing method is used to measure the contact area in nanoindentation. Moreover, the contact area at maximum load is calculated using the load-displacement curve.

Thus, by measuring force-displacement (i.e. stress and strain) for both loading and unloading event of the indenter, information about hardness and elastic modulus of sample can be obtained.

Nanoindentation Instrumentation

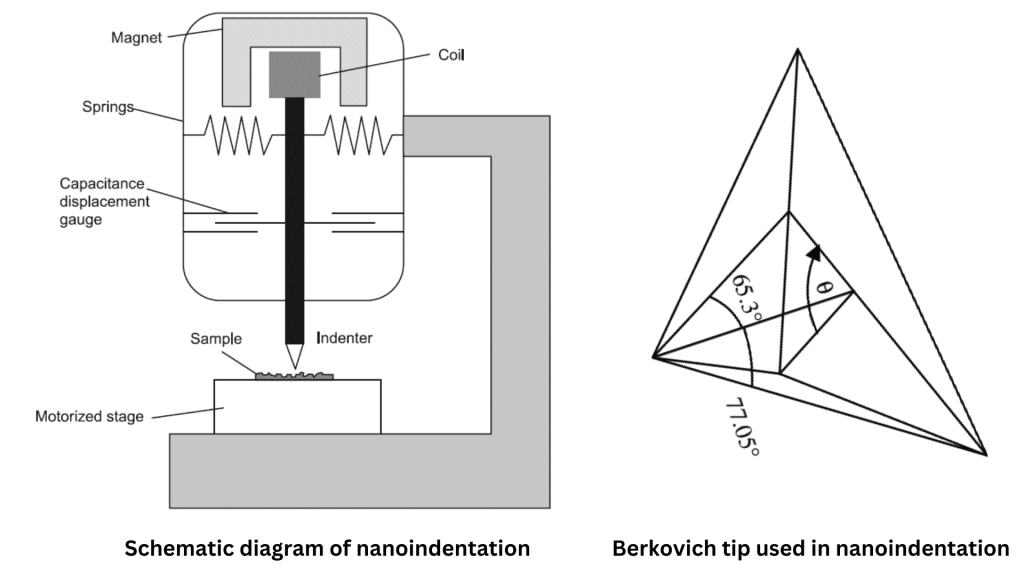

Nanoindentation device also called nanoindenter, contains an indenter tip fabricated by diamond having well defined geometry or surface area. Using Nanoindenter, desired load can be applied and displacement can be measured precisely. In experiment, the indenter tip is lowered till it touches the sample surface. After point of contact is determined, force is increased linearly so the size of indent on sample increases. After a short dwell time, the indenter is unloaded.

In nanoindentation test, small loads and tip sizes are used, so that the indentation area may measure only a few square micrometres or even nanometres. As a result, one common issue is that the contact area is difficult to locate. The indentation may be imaged using atomic force microscopy or scanning electron microscopy techniques, but these methods can be laborious. This issue is typically solved by utilizing an indentor with high-precision geometry, such as a Berkovich tip with a three-sided pyramid geometry. The mechanical properties of sample are then determined from the load-displacement curve.

Load-displacement curve nanoindentation

In Nanoindentation, the load-displacement curve is used to determine the mechanical properties since it provide mechanical fingerprint of materials response to contact deformation (S. V. Hainsworth et al., 1996).

Nanoindentation of polymers

The nanoindentation in polymer is used to measure its mechanical properties. For the determination of the modulus, hardness, and creep improvements following the addition of the filler, nanoindentation is a very useful instrument. When this techniques is used to polymers, the elastic moduli are frequently measured, and the trends in the elastic moduli as a function of penetration depth are sometimes slightly high compared to bulk observations.

Nanoindentation Applications

- Measurement of hardness of substance: Hardness ‘H’ can be roughly given by H = Fmax/A, where Fmax is the maximum force applied and A is the effective area of the indent on the sample and is indirectly calculated from the area of the tip.

- Determination of elastic modulus: The effective elastic modulus can be determined roughly from the load-displacement curve in the case if the initial slope is determined.

FAQs/MCQS

What is Nanoindentation?

Nanoindentation is one of the most frequenty used technique to determine the mechanical properties of nanomaterials.